Global PipeLine Solutions (GPLS)

The

specialist for corrosion resistant and heat resistant stainless steels, duplex,

nickel alloys and titanium

Company Testing and Quality Assurance:

A lot of pictures below

concerning several testing

Flanges and forgings Several testing is possible:

-

X-Ray examination

ASME VIII, DIV1, UW-51 / EN10246-10

Fittings

- Hardness

testing NACE MR0175

/ NACE MR0103 / EN

ISO6506-1 / ISO15156 /

ASTM E10

Welded pipes

and tubes - Liquid dye penetrant testing ASTM E165

/ EN10246-11

-

Ultrasonic testing ASTM

E213 /

ASTM A999 / ASTM A388

/ ASTM A578 /

Seamless

pipes and tubes EN10246-6 / EN10246-7

-

Eddy current testing ASTM E426

/ ASTM A999 /

EN10246-2 / EN10246-3

Stainless Steels - Hydrostatic testing

ASTM A999 / EN10246

-

Mechanical testing ASTM

A370

Nickel

alloys and titanium - Chemical analysis

ASTM A751

-

Tension test / Tensile testing ASTM A370

/ ASTM E21

Integral

finned tubes - Flaring test ASTM A999

/ EN10216-5

-

Flattening test ASTM

A999 /

EN10216-5

Internal

polishing - Grain size test ASTM E112

-

Microstructure examination ASTM E562

Testing

and quality assurance - Macroscopic examination

-

Intergranular corrosion testing (IGC) ASTM A262 practice E / EN

ISO3651-2 Method A / ASTM G48

Industries and

references - Huey Test ASTM A262 practice C

-

Oxalic Acid Etch Test ASTM A262 practice A

Contact us -

PMI Spectrum analysis (Positive material identification) Niton / Spectro

-

Ferrite testing (max. 3% on the weld / base material) Feritscope MP30

-

Impact testing at room temperature or -196°C ASTM

A370 /

ASTM E23 / EN10045-1

-

Roughness examination / Rugosity Mitutoyo

-

WPS/PQR

ASME IX / EN15614

-

Visual inspection

-

Visual inspection

-

Dimensional inspection

-

Ring gage check

-

Go no go check

-

Metallurgical tests

-

Sulphur/carbon analyses

-

Magnetic particle examination

-

Heat treatment diagrams

- Stabilizing heat treatment

-

Special mechanical properties

- NORSOK requirements

-

MESC requirements

-

Fumigation PMI with Spectro

-

certificate EN10204/3.1 and EN10204/3.2

-

…

PMI with Niton hand

gun PMI

results Niton hand gun Special

heat treatment (stabilizing heat treatment)

on elbows of 24” SCH XXS in 321H

Ultrasonic wall thickness measurement Ultrasonic testing of seamless pipes

Flattening test on test piece of 24’’ seamless pipe

IQI on X-Ray films Sharpy impact testing Tensile testing

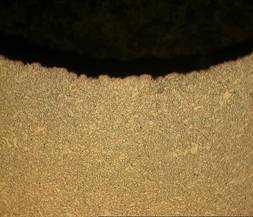

Microscopic examination (200 x enlarged) Dye penetrant investigation Intergranular

corrosion testing

on

duplex 1.4462 pipes on

36’’ 300 lbs RTJ blind flanges

Ultrasonic testing on 24’’ 150

lbs blind flange Packing can be in prefumigated boxes

as per IPCC

Global

PipeLine Solutions NV (GPLS)

Phone:

0032-471-786013

Fax:

0032-9-3307323

Email:

dominiquedeletter@gpls.be